Item Assembly Setup

An item assembly is a different type of item that can incorporate one or more sub-items. The sub-items are used to calculate needed time / materials based on the unit price of the item assembly. The unit price of the assembly will be based on a calculation per unit of the included line items based on how quickly the item can be installed (production rate) and how much material is need to cover the unit ) coverage rate.

The benefits of using an item assembly is that per unit calculations are done that place labor and materials into the project work order in addition to the project total dollars.

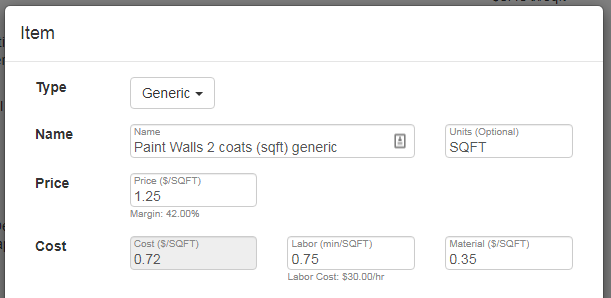

For example if a generic line item is used (non-assembly) that is setup to be $1.25 per square foot to paint 2 coats on interior walls and a 700 square foot room is added there will be a single calculation that will output the price of that room ($1.25 / sq ft x 700 sq ft) for $875 total for the customer to see on the estimate. There will be no hours or paint calculated for the work order for the work that is planned.

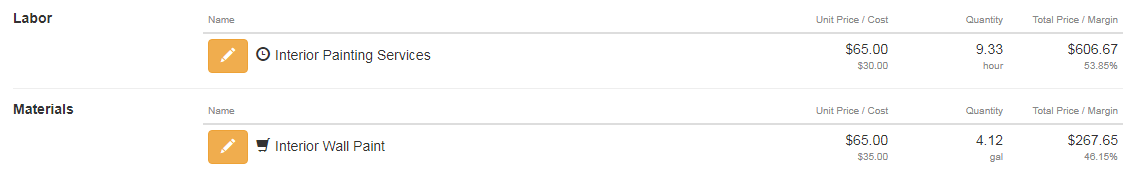

If an assembly version of the same task is put together that has a labor and material as nested items the addition of room with 700 square feet will yield $875 for the customer estimate but will will also calculate the labor hours and paint gallons for the work order.

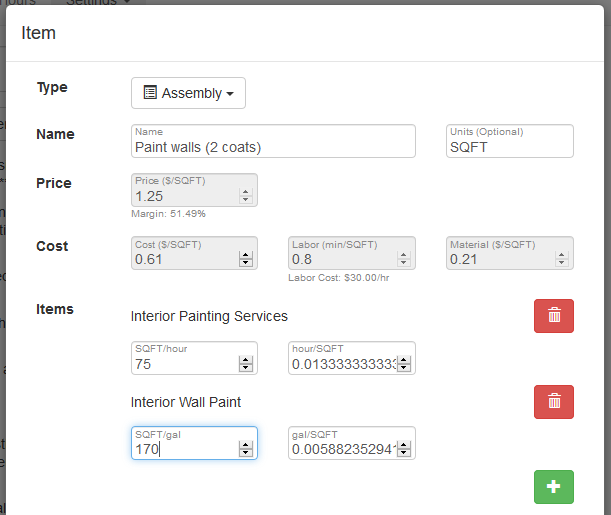

Components of an item assembly

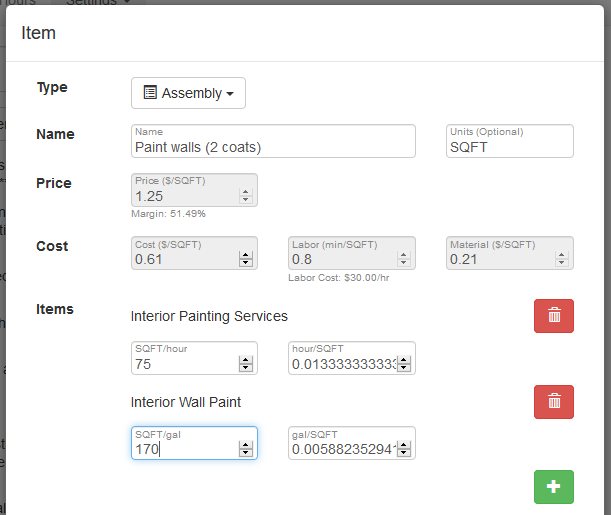

The components of an item assembly typically include labor items and material items. The price per unit cannot be edited directly and is controlled by the price of the labor and the price of the material. The production rate of the labor and the coverage rate of the material can be edited here to change the unit price of the assembly.

How the unit price is calculated

How does this assembly calculate the final price of $1.25 per square foot. There is no way to edit that directly in the assembly. In the right hand column of the 2 items seen in the assembly the value of hours per SQFT and gallons per SQFT are displayed. For the labor example here 0.0133 hours per square foot x 1 square foot x $65 per hour = $0.87 per square foot for the labor portion of this assembly. For the material example 0.00588 gallons per square foot x 1 square foot x $65 per gallon = $0.38 per square foot for the material portion of the assembly.

Labor ($0.87/SQFT) + Material ($0.38 / SQFT) = $1.25 / SQ FT

How the unit price can be changed

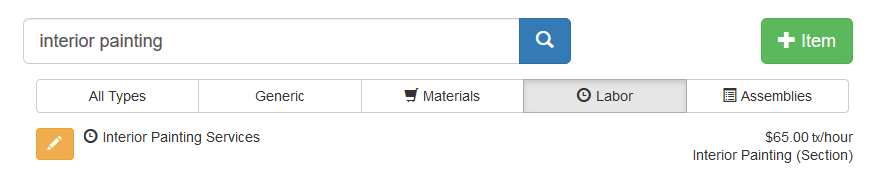

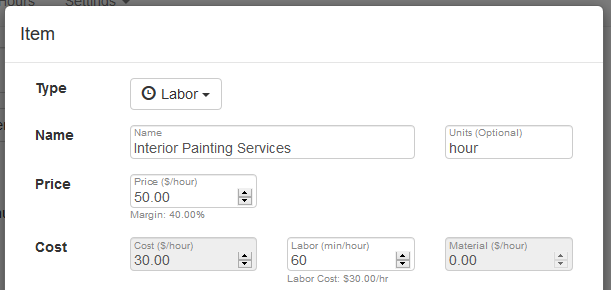

The best practice with any Estimate Rocket assembly is to first track down the price of the base items. In this case Interior Painting Services and Interior Wall paint. Those can be tracked down either by scrolling through the full item list or use the filter buttons to only show labor or material items.

Edit those items and make sure the price is correct. The templates are distributed with a standard $50 per hour price for the Interior Painting Services. If the enterprise version of Estimate Rocket is being used the labor price can also be set. The average labor price is set from Settings > Company information.

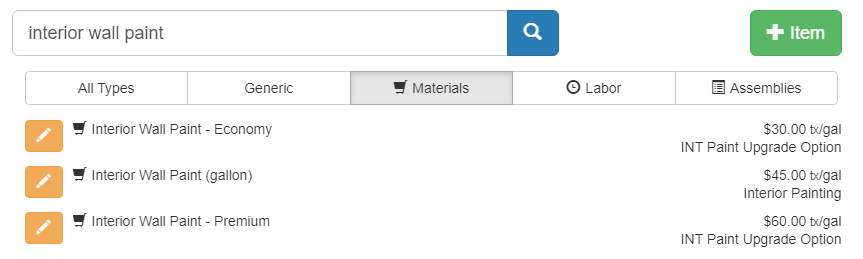

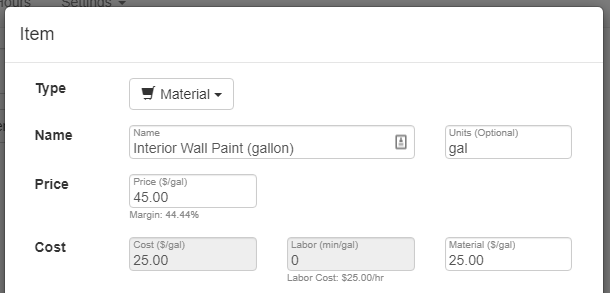

Or the Interior Wall Paint, which is distributed at $45 per gallon. If the enterprise version of Estimate Rocket is being used the cost of the paint can also be set from this screen to be included in the estimated profit margin of the project.

Edit the material to make sure the price is correct for your area.

After the labor and material are priced correctly then move on to the production rate of the labor and the coverage rate of the material. The production rates of all of the painting items are based on PDCA published rates but you can change those to match the crews involved.

The item assemblies are definitely more work to setup than a generic line item. The benefits that will be realized later will be the ease of estimating and putting together a proper work order will save time in the long run.